- #David 3d scanner forum pro#

- #David 3d scanner forum software#

- #David 3d scanner forum download#

- #David 3d scanner forum crack#

Severe cracks in a fielded PET backsheet exposed the tabbing ribbon, creating a.

#David 3d scanner forum software#

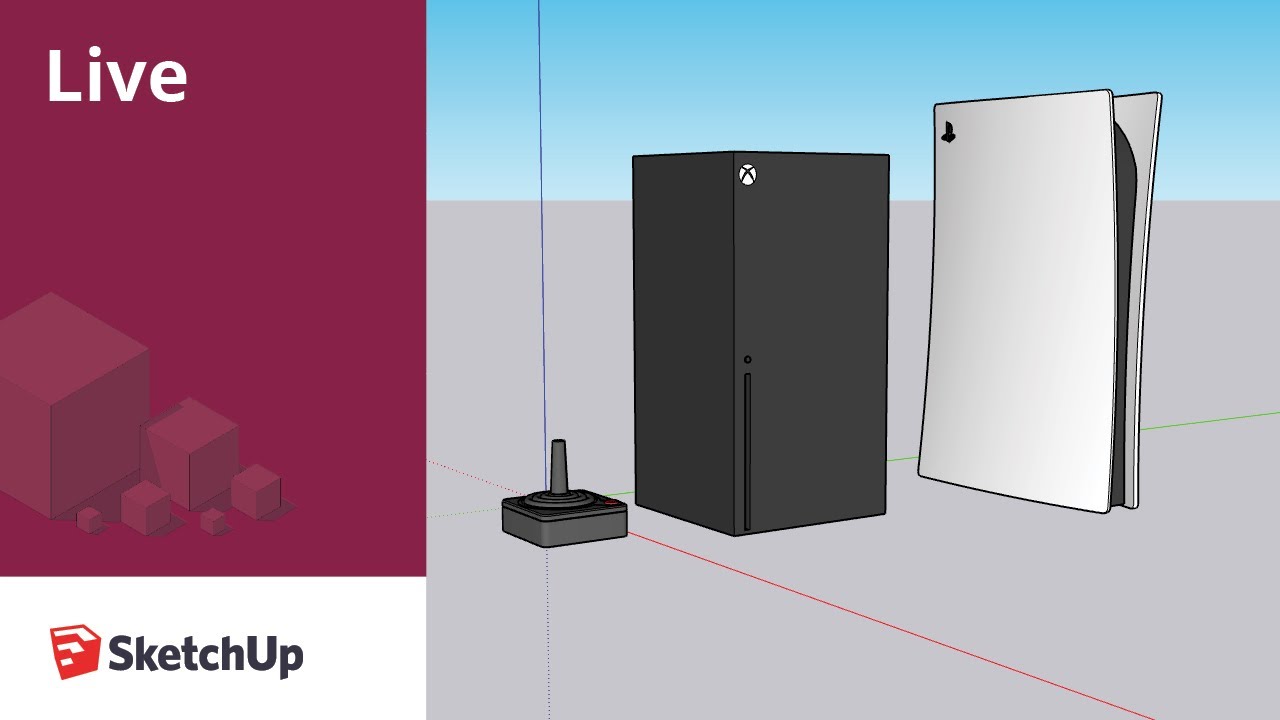

david scanner david scanner software david scanner forum david scanner sls 2 david scanner 3d david scanner .

May not be copied, scanned, or duplicated, in Whole or in part.

#David 3d scanner forum crack#

Quoted in “New DNA Database Helps Crack 1979 N.Y. An Anthology (Los Angeles: Roxbury Publishing Co., 1999), 351. David Alan Sklansky, “Not Your Father's Police Department: Making Sense of the New. Sim- ilar observations on subsurface fatigue crack initiation have been reported earlier by Shiozawa and Lu. Build your own 3D scanner using a Web cam and laser and scan .

#David 3d scanner forum download#

Locate and download DAVID-Laserscanner v.2.6.2 keygen from our site. David Watts for their contribution to sample preparation.

The test-piece was held in position to allow the load to stabilise before each scan. It has been applied to study the 3D crack morphologies and propagation below. Two possible crack tip signals are highlighted by arrows in the image. Linear scanning with longitudinal wave modes from TRL probe at 60°. Thats a collection of open source designs which people upload and has some really cool stuff.David scanner, david scanner software, david scanner 3d, david scanner forum, david scanner turntable, david scanner hp, david scanner software download, david scanner calibration, david scanner sls 2, david scanner diy, david scanner sls 3, david scanner download PLA is much more rigid, has a low melting point and seems to be favoured by the cheaper 3d printers.įor an idea of the kind of stuff people are making you'll want to check out. I'd say ABS is the better one - higher melting point, high impact (same stuff they use for car bumpers).

There are 2 main types of plastic that are used in 3d printing: ABS and PLA. You can find some info and pics of it in the projects section here. The largest thing I've made with mine is a mechanism for an animatronic tail - basically a set of snap together universal joints. You can make structural and mechanical parts as long as the individual feature size is big enough (things like vertices for metal or wooden frames, large gears etc). I mainly use it to make cases for electronic projects (which I have to do in sections due to the 14cm size limit (which is actually closer to 10 if you want to avoid warping). Its ok for hobby stuff but not if youre working professionally. Roland also makes some piezo needle desktop scanners that are slow but produce good results for a desktop unit if the model you are scanning is suitable, and it is also a CNC milling machine. Personally I have not invested in my own 3D scanning equipment because I find it easy enough to simply model my stuff in Solidworks from scratch faster.

#David 3d scanner forum pro#

And some of the scans are amazing, not as good as pro stuff but still IMO plenty good for many DIY projects. This system uses a simple laser pointer or a projector light. Look at this system and look at the real scans users have achieved in the gallery. You get high quality prints, not spaghetti noodle looking models.Īs for scanning there are lots of options, and some of the DIY stuff is really amazing. IMO they have great prices and they do quick turns. I have used and will continue to use for most of my printing. The DIY 3D printing stuff is really far inferior to the big $ machines you can hire out.

0 kommentar(er)

0 kommentar(er)